Ever wanted to personalize your footwear? Or maybe you’re just curious about the possibilities of 3D printing? Well, you’re in for a treat! This guide will walk you through the process of 3D printing Crocs. Yes, you read that right – you can 3D print your own Crocs! It’s a fascinating project that combines the comfort of Crocs with the customization potential of 3D printing.

This isn’t a quick print-and-wear project. It requires patience and a willingness to learn. You’ll need to understand 3D modeling, slicing, and printing parameters. But don’t worry, we’ll break it down step-by-step. By the end, you’ll have the knowledge to create your own unique Crocs, tailored to your style and needs.

Get ready to dive into the world of 3D printing and discover how to bring your footwear fantasies to life. Let’s get started!

What You’ll Need to 3d Print Crocs

Before we jump into the printing process, let’s gather the necessary tools and materials. This will ensure a smooth and successful project. Here’s a comprehensive list:

- 3D Printer: A 3D printer capable of printing flexible filaments is crucial. Fused Deposition Modeling (FDM) printers are the most common type for this project. Consider a printer with a heated bed for better adhesion. Look for a printer with a build volume large enough to accommodate the size of your Croc design.

- Flexible Filament: This is the most important material. TPU (Thermoplastic Polyurethane) is the most popular choice for its flexibility, durability, and rubber-like properties. Other options include TPE (Thermoplastic Elastomer). The shore hardness of the filament (typically between 75A-95A) will affect the final flexibility of your Crocs. Experiment to find your preferred feel.

- 3D Modeling Software: You’ll need software to design or modify the Croc model. Popular choices include:

- Tinkercad: A free, user-friendly option for beginners.

- Fusion 360: A more advanced, but still accessible, option with a free license for hobbyists.

- Blender: A powerful open-source option, often used for more complex designs.

- Slicer Software: This software converts your 3D model into instructions for your printer. Popular choices include:

- Cura: A widely used, free, and versatile slicer.

- PrusaSlicer: Excellent for Prusa printers, but compatible with others.

- Calipers: Essential for measuring your feet and the existing Crocs (if you’re modifying a design).

- Adhesive (Optional): For assembling multiple parts or reinforcing weak areas. Cyanoacrylate glue (super glue) works well with TPU.

- Support Removal Tools: If your design requires supports, you’ll need tools to remove them.

- Safety Gear: Eye protection and adequate ventilation are recommended, especially when working with heated plastics.

Designing or Finding a 3d Model of Crocs

You have two main options here: design your own Crocs from scratch or find a pre-made model. Each has its own advantages.

Designing Your Own Crocs

This gives you complete control over the design, allowing for maximum customization. However, it requires a good understanding of 3D modeling. Here’s a general approach: (See Also: Does Macy’s Have Crocs? Your Ultimate Guide!)

- Foot Measurement: Accurately measure your foot (or the foot of the person who will wear the Crocs) using calipers. Include length, width, and any other relevant dimensions.

- Base Shape: Create the basic shape of the Croc sole. This can be a simple rectangular shape to start, then add the curved shape of the Croc sole.

- Detailed Design: Add details such as the toe box, heel strap attachments, and any decorative elements. Consider the thickness of the material and how it will flex.

- Holes and Ventilation: Design the iconic holes in the Crocs. Consider their size, shape, and placement for optimal ventilation.

- Testing and Iteration: Print a small section of the design to test the fit and flexibility. Make adjustments as needed.

Finding a Pre-Made Model

This is a quicker option, especially if you’re new to 3D modeling. You can find models on various online platforms:

- Thingiverse: A vast repository of free 3D models.

- Cults3D: Offers a mix of free and paid models.

- MyMiniFactory: Focuses on quality-vetted models.

When choosing a model, consider the following:

- Size: Make sure the model is available in the correct size or can be easily scaled.

- Reviews: Check reviews from other users to assess the print quality and fit.

- File Format: Ensure the model is in a format compatible with your slicer software (typically STL or OBJ).

- Customization: Decide if you want to modify the design. Some models are easily customizable, while others are not.

Slicing the 3d Model

Once you have your model, you’ll need to slice it using slicing software. This process prepares the model for printing by converting it into layers that the 3D printer can understand. Here’s a breakdown of the key settings for printing Crocs with TPU:

- Filament Type: Select the correct filament type (TPU or TPE) in your slicer settings. This will automatically adjust some parameters.

- Layer Height: Choose a layer height that balances print time and detail. A layer height of 0.2mm – 0.3mm is a good starting point for Crocs. Finer layers (e.g., 0.1mm) will result in smoother surfaces but will increase print time.

- Infill: The infill percentage affects the flexibility and durability of the Crocs. A lower infill percentage (e.g., 10-20%) will make the Crocs more flexible, while a higher infill (e.g., 30-40%) will make them more rigid. Consider the design and intended use. The infill pattern can also affect the flexibility; a grid or gyroid pattern is often used.

- Print Speed: Reduce the print speed, especially for the outer perimeters, to ensure good layer adhesion and prevent stringing. A print speed of 20-40 mm/s is usually recommended for TPU.

- Temperature: Experiment with the nozzle and bed temperatures based on your specific TPU filament. Start with the manufacturer’s recommended settings, and adjust as needed. Usually, the nozzle temperature will be around 210-230°C and the bed temperature around 40-60°C.

- Retraction: TPU can be prone to stringing. Adjust retraction settings to minimize this. Experiment with retraction distance (1-3 mm) and retraction speed (20-40 mm/s).

- Supports: Croc designs often require supports, especially for overhangs (like the heel strap). Choose the appropriate support type (e.g., tree supports or grid supports) and ensure they are easily removable. Consider using a support interface for easier removal.

- Build Plate Adhesion: TPU can sometimes have adhesion issues. Use a brim or raft to help the print stick to the bed. A brim is usually sufficient.

Important Note: Always perform test prints (e.g., small cubes or flex tests) to fine-tune your settings before printing the entire Croc. Every printer and filament combination is unique.

Printing the Crocs

Now comes the exciting part – the printing process! Here’s what to expect: (See Also: Are Crocs Good for Children’s Feet? A Parent’s Guide)

- Prepare the Printer: Ensure your printer is properly calibrated and the bed is level. Clean the print bed with isopropyl alcohol to improve adhesion.

- Load the Filament: Load the TPU filament into your printer. Make sure the filament path is smooth and unobstructed. TPU can be more prone to tangling than other materials.

- Start the Print: Preheat the printer to the temperatures specified in your slicer settings. Start the print and monitor it closely, especially during the first few layers.

- Monitor the Print: Keep an eye on the print for any issues, such as warping, stringing, or layer separation. If problems arise, pause the print and make adjustments to your settings.

- Cooling: TPU often benefits from moderate cooling. Experiment with fan settings to optimize print quality without compromising layer adhesion.

- Print Time: Printing Crocs can take a significant amount of time, potentially several hours per shoe. Be patient and allow the printer to do its work.

Post-Processing and Finishing

Once the print is complete, you’ll need to remove the supports and any imperfections.

- Remove Supports: Carefully remove the supports using the appropriate tools. Be gentle to avoid damaging the Croc.

- Clean Up: Trim away any remaining support material or imperfections with a sharp knife or sanding.

- Assembly (If Necessary): If your design involves multiple parts, assemble them using adhesive if needed.

- Testing and Fit: Try on the Crocs to ensure a good fit. Make any necessary adjustments.

- Finishing Touches (Optional): You can further customize your Crocs with paint, decorations, or other embellishments.

Troubleshooting Common 3d Printing Issues

Printing with TPU can present some challenges. Here’s how to address common issues:

- Poor Bed Adhesion:

- Solution: Clean the bed with isopropyl alcohol. Use a brim or raft. Increase bed temperature slightly. Ensure the bed is level.

- Stringing:

- Solution: Adjust retraction settings (distance and speed). Reduce print temperature. Slow down print speed.

- Warping:

- Solution: Ensure proper bed adhesion. Use a brim. Reduce bed temperature. Print in an enclosure to maintain consistent temperature.

- Layer Separation:

- Solution: Increase print temperature. Reduce print speed. Ensure good layer adhesion by optimizing cooling.

- Clogging:

- Solution: TPU is flexible and can sometimes cause clogs. Ensure the filament path is smooth and free of obstructions. Use a direct-drive extruder if possible. Increase nozzle temperature slightly.

- Inconsistent Extrusion:

- Solution: Check the extruder gear for wear. Ensure the filament is feeding smoothly. Calibrate the extruder steps.

- Print Not Sticking to Supports:

- Solution: Adjust support interface settings in your slicer. Increase support density. Reduce the distance between the model and the supports.

Advanced Techniques and Customization

Once you’ve mastered the basics, you can explore more advanced techniques and customization options:

- Multi-Material Printing: Use a printer with multiple extruders to print Crocs with different colors or materials.

- Variable Layer Height: Adjust the layer height dynamically during the print for finer detail in specific areas.

- Texture and Embossing: Add textures or embossed patterns to the Crocs for a unique look.

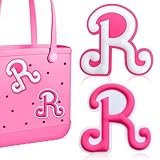

- Custom Jibbitz: Design and 3D print your own Jibbitz (the charms that go on Crocs).

- Incorporating Electronics: Integrate LEDs or other electronics into your Croc design.

- Design Modifications: Add custom logos, names, or other personalized elements to the design.

- Experiment with Different Filaments: Explore different TPU or TPE filaments with varying shore hardness and properties to achieve different levels of flexibility and durability.

Safety Considerations

3D printing involves some safety considerations:

- Ventilation: Ensure adequate ventilation to remove fumes released during printing.

- Eye Protection: Wear safety glasses to protect your eyes from debris.

- Heat Safety: Be careful when handling the hot nozzle and bed.

- Electrical Safety: Use a properly grounded 3D printer and avoid overloading electrical circuits.

- Filament Handling: Store filament in a dry place to prevent moisture absorption, which can affect print quality.

Cost Analysis

The cost of 3D printing Crocs depends on several factors: (See Also: How Mych Are Crocs? A Guide to Crocs Prices & Styles)

- Filament Cost: TPU filament typically costs around $20-$40 per kilogram.

- Electricity Cost: The electricity used by your printer will add to the cost. This is usually a small amount.

- Printer Cost: If you don’t already own a 3D printer, the initial cost will be significant.

- Design Time: If you design your own Crocs, factor in the time spent on design and iteration.

- Failed Prints: Account for the cost of filament wasted on failed prints.

Generally, the cost per pair of Crocs can range from a few dollars for the filament to potentially over $100 if you factor in the cost of a printer. The cost can be reduced by using free designs and optimizing print settings.

Final Thoughts

Printing your own Crocs is a rewarding project that combines creativity with functionality. It’s a great way to personalize your footwear and explore the capabilities of 3D printing. While it requires some learning and experimentation, the results are well worth the effort. You’ll gain a deeper understanding of 3D printing, design, and materials.

Remember to start with the basics, experiment with different settings, and be patient. Don’t be afraid to make mistakes; they’re part of the learning process. With a little practice, you’ll be able to create custom Crocs that reflect your unique style. Embrace the challenge, and enjoy the journey of bringing your footwear ideas to life!

Recommended Products