Ever wondered about the history of those trusty soccer cleats that help you dominate the pitch? They’ve come a long way from rudimentary footwear! The evolution of soccer cleats is a fascinating journey, reflecting advancements in technology, the changing demands of the game, and the relentless pursuit of peak performance.

From simple leather boots to the high-tech masterpieces we see today, the story of soccer cleats is a testament to human ingenuity. It’s a tale of innovation driven by the desire to gain a competitive edge and make the beautiful game even more thrilling. Let’s lace up and explore the exciting story of how soccer cleats were invented and how they’ve evolved over time.

We’ll delve into the early days of the sport, the challenges faced by players, and the groundbreaking innovations that have shaped the cleats we know and love. Get ready to discover the secrets behind the perfect strike, the optimal grip, and the comfort that allows you to play your best. It’s a journey through time, technology, and the passion for football.

The Genesis of Football Footwear: Early Days

Before the sophisticated cleats of today, football players made do with whatever footwear they could find. In the early days of the sport, which began to formalize in the mid-19th century, there were no specialized boots. Players simply wore their everyday work boots. These were typically heavy, leather boots designed for durability rather than agility or performance on the field.

The early games were rough and tumble affairs, with little consideration for player safety or specialized equipment. The boots offered minimal grip on the muddy and often uneven playing surfaces. This resulted in frequent slips, falls, and injuries. The focus was on protecting the feet from the elements and the rough treatment of the game, not on enhancing performance.

The materials used were basic: thick leather for the uppers and soles, with nails or studs hammered into the soles to provide some traction. These rudimentary studs were often made of metal or leather. This was a significant step toward improving grip, but they were still far from ideal.

The weight of these early boots was a major drawback. They were cumbersome and made it difficult for players to move quickly or change direction. The leather, when wet, became even heavier and less flexible, further hindering performance. The boots also provided little in the way of ankle support, making players more susceptible to injuries.

Despite these limitations, these early boots were the foundation upon which modern soccer cleats would be built. They represented the first attempts to adapt footwear to the specific demands of the game.

The Emergence of Specialized Boots

As football grew in popularity, the need for better footwear became increasingly apparent. Players and manufacturers began to recognize the limitations of the standard work boots and the potential for improving performance through specialized designs.

Around the late 19th century, the first specialized football boots began to emerge. These boots were still made of leather, but they incorporated several key improvements over their predecessors. They were lighter, more flexible, and featured improved stud configurations.

One of the most significant innovations was the use of studs. Initially, these were simple metal or leather attachments nailed to the soles. However, over time, the designs became more sophisticated, with studs of varying shapes and sizes being introduced to optimize grip on different surfaces.

The design of the boots also began to evolve. The uppers were made more supple to allow for greater flexibility and comfort. The boots were often laced higher up the ankle to provide better support. This was a crucial development, as it helped to reduce the risk of ankle injuries, a common problem in the early days of the sport.

These early specialized boots were a significant step forward, offering players a tangible advantage on the field. They allowed for greater speed, agility, and control. They were also the first evidence of the increasing influence of technology on the game of football.

The Role of Leather and Early Manufacturing Techniques

Leather was the primary material used in the construction of soccer cleats for many decades. Its durability, flexibility, and ability to mold to the foot made it ideal for the demands of the game. However, the use of leather also presented several challenges.

One of the biggest issues was the weight of the boots. Leather boots could become very heavy, especially when wet, which significantly impacted players’ performance. Manufacturers experimented with different types of leather and construction techniques to minimize weight without compromising durability.

The manufacturing process was initially very basic. Boots were often handmade, with each pair taking a significant amount of time and skill to produce. This made the boots expensive and limited their availability. However, as demand grew, manufacturers began to adopt new techniques to speed up production.

The introduction of the sewing machine was a game-changer. It allowed for faster and more consistent stitching, leading to improved quality and reduced costs. The use of molds also became more widespread, enabling manufacturers to create boots in standardized sizes and shapes.

Despite these advancements, leather remained the dominant material for many years. It was only with the advent of synthetic materials that the limitations of leather were truly overcome.

Key Individuals and Companies in Early Cleat Development

Several individuals and companies played pivotal roles in the early development of soccer cleats. Their innovations and contributions helped to shape the game and improve the performance of players. (See Also: How to Measure for Softball Cleats: A Step-by-Step Guide)

One of the earliest innovators was H.J. Cobb, who patented a design for football boots in the 1890s. His boots featured studs designed to improve grip and were a significant step forward in cleat technology.

The company Gola, founded in 1905, was one of the first to specialize in sports footwear. They produced a range of football boots that were popular with players at all levels of the game. Gola’s boots were known for their quality and durability, and they helped to establish the brand as a leading provider of sports equipment.

Hummel, a Danish company, was another pioneer in the field of football footwear. Founded in 1923, Hummel produced innovative boots that incorporated new technologies and materials. Their boots were worn by many of the top players of the time.

These companies and individuals were instrumental in shaping the evolution of soccer cleats. Their innovations and dedication to improving the game helped to create the modern cleats we know and love.

The Evolution of Cleats: From Leather to Synthetics

The 20th century saw a period of rapid innovation in soccer cleat design. The development of new materials and manufacturing techniques led to significant improvements in performance, comfort, and durability.

One of the most significant changes was the shift from leather to synthetic materials. Synthetics offered several advantages over leather, including lighter weight, greater water resistance, and improved durability. They also allowed for more precise control over the design and construction of the boots.

The introduction of injection molding revolutionized the manufacturing process. This allowed manufacturers to create boots with complex shapes and designs, leading to improved fit and performance. Injection molding also made it possible to produce boots in larger quantities, making them more affordable and accessible to players.

The design of the studs also underwent significant changes. The early metal and leather studs were replaced with plastic and rubber studs, which provided better grip and were less likely to cause injuries. Stud configurations became more sophisticated, with different designs being developed for different playing surfaces.

These advancements transformed the game of football. They allowed players to move faster, change direction more quickly, and exert greater control over the ball. They also helped to reduce the risk of injuries, making the game safer and more enjoyable for players.

The Rise of Synthetic Materials

The introduction of synthetic materials, such as nylon and polyurethane, was a turning point in the history of soccer cleats. These materials offered several advantages over leather, including lighter weight, greater water resistance, and improved durability. They also allowed manufacturers to experiment with new designs and construction techniques.

Nylon was one of the first synthetic materials to be widely adopted. It was used in the uppers of the boots, providing a lightweight and durable alternative to leather. Polyurethane was also used, particularly in the soles of the boots, where its flexibility and resistance to wear were highly valued.

The use of synthetic materials allowed manufacturers to create boots that were more comfortable and better suited to the demands of the game. The boots were lighter, which helped players to move faster and conserve energy. They were also more water-resistant, which meant that they didn’t become heavy and cumbersome in wet conditions.

The shift to synthetic materials also had a significant impact on the manufacturing process. Synthetic materials could be molded and shaped more easily than leather, allowing for more complex designs and improved fit. This led to a greater variety of boots being available, with different designs being tailored to the specific needs of different players.

Stud Configuration Innovations

The design and configuration of studs have always been a critical aspect of soccer cleat development. The studs are responsible for providing grip and traction on the playing surface, allowing players to move quickly, change direction, and maintain their balance.

Early studs were simple metal or leather attachments. However, over time, the designs became more sophisticated, with different shapes and sizes being introduced to optimize grip on different surfaces. The placement and arrangement of the studs also evolved, with manufacturers experimenting with different configurations to improve performance.

One of the key innovations was the introduction of conical studs. These studs provided excellent grip and were less likely to cause injuries than the earlier metal studs. They also allowed for greater flexibility and freedom of movement.

The development of bladed studs was another significant advancement. These studs provided even greater grip and were particularly effective on soft or muddy surfaces. However, they were also more likely to cause injuries if used on hard surfaces.

Today, stud configurations are highly sophisticated, with different designs being tailored to specific playing surfaces and player preferences. Some cleats feature interchangeable studs, allowing players to customize their grip to suit the conditions. The ongoing innovation in stud technology is a testament to the importance of grip and traction in the modern game. (See Also: Do Puma Cleats Come at True Size? A Sizing Guide)

The Impact of Injection Molding

Injection molding was a game-changing technology in the manufacturing of soccer cleats. This process allowed manufacturers to create boots with complex shapes and designs, leading to improved fit and performance. It also enabled them to produce boots in larger quantities, making them more affordable and accessible to players.

Before injection molding, boots were often made by hand, with each pair taking a significant amount of time and skill to produce. The introduction of injection molding allowed manufacturers to automate the process, reducing production time and costs. This, in turn, led to lower prices for consumers and a greater variety of boots being available.

Injection molding also allowed for greater precision in the design and construction of the boots. Manufacturers could create boots with specific features, such as reinforced heels, padded ankles, and customized stud configurations. This led to significant improvements in comfort, support, and performance.

The impact of injection molding on the soccer cleat industry was profound. It revolutionized the manufacturing process, making it possible to produce high-quality boots at a fraction of the cost of traditional methods. This, in turn, helped to popularize the game and made it accessible to players of all levels.

Key Brands and Models: Pioneers of Modern Cleats

Several brands have played a pivotal role in the evolution of modern soccer cleats. Their innovations and dedication to improving the game have left a lasting impact on the sport. Here are some of the key brands and models that have shaped the industry:

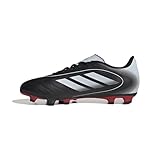

- Adidas: Adidas has been a dominant force in the soccer cleat market for decades. Their iconic models, such as the Copa Mundial and Predator, have been worn by some of the greatest players in the world. Adidas has consistently pushed the boundaries of cleat technology, introducing innovative features like the laceless design and the Primeknit upper.

- Nike: Nike entered the soccer market later than Adidas, but they quickly established themselves as a major player. Their Mercurial line, worn by stars like Cristiano Ronaldo, is known for its lightweight design and focus on speed. Nike has also been a leader in using sustainable materials and innovative construction techniques.

- Puma: Puma has a long and rich history in soccer. Their cleats have been worn by legendary players like Pelé and Maradona. Puma is known for its focus on style and performance, with models like the King and Future series being popular choices among players of all levels.

- Umbro: Umbro, a British brand, has a strong heritage in soccer. Their cleats are known for their classic design and focus on comfort. Umbro has a loyal following among players who appreciate their traditional approach to cleat design.

These brands have consistently pushed the boundaries of cleat technology, introducing innovative features and materials that have improved the performance and comfort of players around the world. Their contributions have helped to shape the modern game and make it more exciting and enjoyable for players and fans alike.

The Technology of Today’s Cleats: Innovation at Its Peak

Modern soccer cleats are marvels of engineering. They incorporate cutting-edge technologies to enhance performance, comfort, and durability. From advanced materials to sophisticated stud configurations, today’s cleats are designed to give players a competitive edge.

One of the most significant advancements is the use of lightweight synthetic materials, such as knitted uppers and composite soles. These materials provide a superior fit, improved breathability, and enhanced flexibility. The use of 3D printing is also becoming more prevalent, allowing for customized designs and personalized fits.

Stud configurations have become highly specialized, with different designs being tailored to specific playing surfaces and player preferences. Some cleats feature interchangeable studs, allowing players to customize their grip to suit the conditions. Other innovations include the integration of sensors and data analytics, which provide valuable insights into player performance.

The focus on sustainability is also growing. Manufacturers are increasingly using recycled materials and eco-friendly manufacturing processes. This reflects a growing awareness of the environmental impact of the industry and a commitment to creating more sustainable products.

Advanced Materials and Construction

The materials used in modern soccer cleats are a far cry from the heavy leather of the past. Today’s cleats are made from a range of advanced materials designed to optimize performance, comfort, and durability.

Knitted uppers: Knitted uppers, often made from materials like Flyknit or Primeknit, provide a sock-like fit that molds to the foot. They are lightweight, breathable, and offer excellent flexibility. They also allow for more precise control over the design and construction of the boot.

Composite soles: Composite soles, often made from materials like carbon fiber or TPU (thermoplastic polyurethane), provide excellent strength and flexibility. They are also lightweight, which helps to reduce the overall weight of the boot. Composite soles are often designed with specific flex zones to enhance natural foot movement.

Microfiber linings: Microfiber linings provide a comfortable and supportive fit. They help to wick away moisture and prevent blisters. They also enhance the overall durability of the boot.

These advanced materials are combined using sophisticated construction techniques, such as heat-sealing and bonding, to create boots that are both high-performing and durable. The result is a new level of comfort and performance for players of all levels.

Stud Design and Performance

Stud design is a critical aspect of soccer cleat performance. The studs are responsible for providing grip and traction on the playing surface, allowing players to move quickly, change direction, and maintain their balance. Modern stud designs are highly sophisticated, with different configurations being tailored to specific playing surfaces and player preferences.

Conical studs: Conical studs are versatile and provide good grip on a variety of surfaces. They are less likely to cause injuries than bladed studs and offer excellent flexibility.

Bladed studs: Bladed studs provide excellent grip on soft or muddy surfaces. They are designed to penetrate the ground and provide maximum traction. However, they can be more likely to cause injuries if used on hard surfaces. (See Also: How to Fit Sm-Sh51 Cleats: Your Ultimate Guide)

Hybrid studs: Hybrid studs combine the features of conical and bladed studs. They offer a balance of grip, flexibility, and injury prevention.

Interchangeable studs: Some cleats feature interchangeable studs, allowing players to customize their grip to suit the conditions. This is particularly useful for players who play on a variety of surfaces.

The ongoing innovation in stud technology is a testament to the importance of grip and traction in the modern game. Manufacturers are constantly experimenting with new designs and materials to improve performance and reduce the risk of injuries.

Smart Cleats and Data Analytics

The integration of technology into soccer cleats is revolutionizing the way players train and perform. Smart cleats, equipped with sensors and data analytics, provide valuable insights into player performance, allowing players and coaches to optimize their training and strategy.

Sensors: Sensors embedded in the cleats track a variety of metrics, including speed, acceleration, distance covered, and shot power. They can also provide data on player movement, such as footwork patterns and agility.

Data analytics: The data collected by the sensors is analyzed to provide insights into player performance. This information can be used to identify areas for improvement, such as areas of weakness and areas where the player excels. It can also be used to track progress over time.

Personalized training: Smart cleats allow for personalized training programs tailored to the individual needs of each player. Coaches can use the data to create specific drills and exercises to help players improve their skills and performance.

The use of smart cleats and data analytics is still in its early stages, but it has the potential to transform the game of soccer. By providing players and coaches with valuable insights into player performance, these technologies can help to unlock the full potential of every player.

Sustainability and the Future of Cleats

Sustainability is becoming an increasingly important consideration in the design and manufacturing of soccer cleats. Manufacturers are increasingly using recycled materials and eco-friendly manufacturing processes to reduce the environmental impact of their products.

Recycled materials: Many cleats now incorporate recycled materials, such as plastic bottles and fishing nets, in their construction. This helps to reduce waste and conserve resources.

Eco-friendly manufacturing: Manufacturers are also adopting eco-friendly manufacturing processes, such as reducing water usage and using renewable energy sources. This helps to minimize the environmental impact of the production process.

Durable designs: The focus on durability is another way that manufacturers are contributing to sustainability. By creating cleats that last longer, they reduce the need for frequent replacements, which, in turn, reduces waste.

The future of soccer cleats will likely see even greater emphasis on sustainability. Manufacturers will continue to explore new materials and technologies to create cleats that are both high-performing and environmentally friendly. This will help to ensure that the game of soccer remains sustainable for generations to come.

Verdict

From humble beginnings to the high-tech marvels of today, the evolution of soccer cleats reflects the dynamic nature of the sport itself. The relentless pursuit of performance, comfort, and safety has driven innovation, resulting in footwear that enhances players’ abilities on the pitch.

The journey from heavy leather boots to lightweight, precision-engineered cleats is a testament to human ingenuity and the enduring passion for football. As technology continues to advance, we can expect even more groundbreaking innovations in cleat design, further shaping the future of the game.

The next time you lace up your cleats, remember the rich history behind them. Appreciate the evolution of this essential piece of equipment and the role it plays in making the beautiful game even more exciting and enjoyable. The story of soccer cleats is a story of progress, dedication, and the unwavering love for football.

Recommended Products